Eliminate Waste and Maintain Highest Quality & Sterility.

Labcon’s 12,000-square-meter eco-efficient manufacturing facility in Petaluma, California runs 24 hours a day year-round and produces a daily amount of 4 million pieces used in 1,300 finshed goods. To ensure this facility runs as eco-efficiently as possible, Labcon is focused on increasing resource efficiency, utilizing renewable resources, reducing energy consumption, eliminating harmful chemicals, and reducing waste and emissions.

With continued improvement to Labcon’s design and manufacturing facility in Petaluma, California USA, the energy content to produce a case of product has been reduced by more than 50% since 2000.

The Earth Friendly® Promise

The Earth Friendly® symbol is proudly displayed on our product packaging and literature, but Earth Friendly® is more than just a slogan, it is a promise to the planet. To keep that promise, Labcon has implimented sustainable goals and practices that address the environmental impact of product packaging, waste, and life cycles. Labcon designs and manufactures reusable, refillable, and recyclable products that use less plastic, incorporates more recycled and recyclable materials, revolutionary bioplastics, and minimal packaging. Labcon’s manufacturing plant uses renewable energy and efficient, waste-free machines to manufacture every product.

Toward Zero Manufacturing Waste

Manufacturing Results

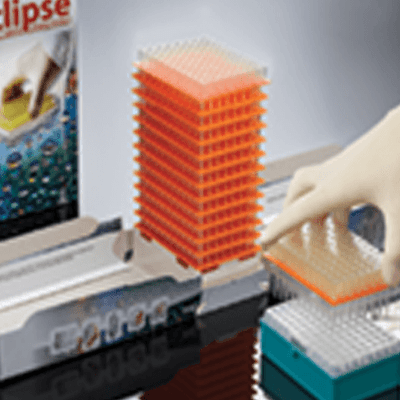

Advanced all electric injection molding machines reduce energy consumption by up to 60% compared to hydraulic machines. Over 90% of Labcon products are molded, assembled, packaged, and distributed from our Petaluma manufacturing facility with remaining components sourced from local partners within 160 kilometers. Since the year 2000 we have reduced the waste per kilogram in making our products by 86% per case.

Electric Molding Machines Use 60% Less60%

Reduction in Energy Usage90% of Product Made and Packed Onsite 90%

Local & Onsite ProductionReduced Waste per Kilogram by 86% per Case86%

Reduction in Waste per Kilogram

Making an

Earth Friendly Company

Watch a short video about the steps Labcon has taken on our journey to become a more sustainable company.